I went spearfishing with a friend and after several attempts at shooting fish underwater, I realized that I would need my own speargun to practice with. Another friend thought it was a good idea and said he would help me. This was good because in hindsight there was no way I would have been able to do it by myself.

The Tigak did not always use spearguns, of course. Before, their ancestors used a combination of long wooden spears and “poison rope” to go out and collect fish. Many people in our village still maintain their ability to hand spear fish, while the “poison rope” method is no longer legal in Papua New guinea. However, apparently sometime during the 1950’s some missionaries living in a neighboring language group introduced the speargun and over time this knowledge passed on to the Tigak.

The speargun is an important tool in the culture and spearfishing is solely a male activity. Most young men, single or married, have a working speargun ready to roll for getting fish. Because fish are a main staple both for eating and selling at the market, a lot of men spear fish almost daily using their spearguns. Interestingly, much of the spearfishing takes place during the night.

When having my speargun made, I decided that I would attempt to have it constructed in the same fashion that people normally make their spearguns out here as much as possible, using the same materials.

At this point, you also might be wondering why I even need a speargun. For one thing, its awesome. Secondly, I want to be able to identify and participate with the younger guys in our village through this important kind of shared activity. I hope building this speargun will open the door to friendships with them that have up to this point been difficult to build.

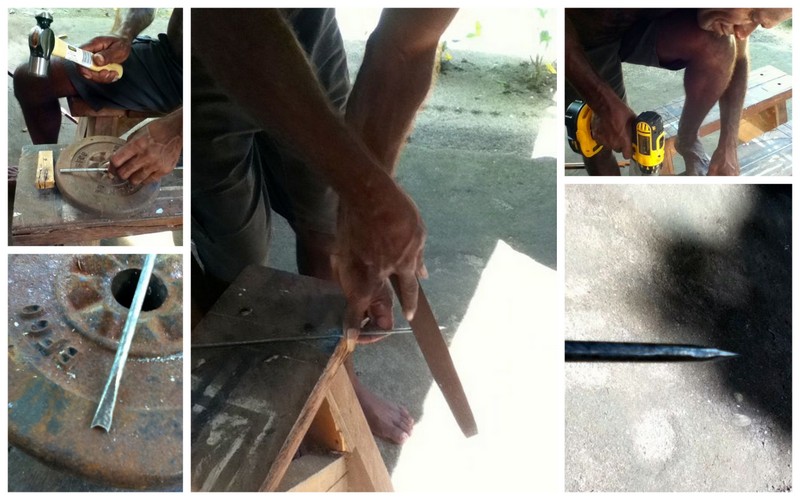

Making the Speargun

First thing we needed to do was find a piece of strong wood. After checking some off-cuts in my shed and coming up short, my friend said he had one at his house we could use. I grabbed my large hand planer and we went over to his house.

When we arrived at his house he grabbed the wood, sawed off some excess length and began cutting it down using his machete. After cutting the area needed to grip, he used a planer to even out the whole thing. Then I spent some time sanding it, after which I painted a design into it and then varnished it a few times.

I’m not going to lie, it looked good.

The next step was to drill the holes needed for the trigger system. At this point you might be asking why I would be using a drill if I wanted my speargun to be made in the same fashion as people normally make out here, because who would have a drill? That would be a great question, and the answer is simple: we missionaries provide the hole drilling for people speargun’s out here. Throughout the week various people throughout our village come to our house to have holes drilled in their speargun or spears. Its just one of the services we provide. 😉 After drilling the holes, it was time to assemble the remainder of the parts.

A lot of random parts went into this, and I won’t go into detail here. Basically it included a “barrel” type piece mounted on using flat rubber from a tire and a rounded piece of rubber also tied on using the tire rubber. At the ends of the rounded rubber, galvanized wire was fastened to attach to the spear in preparation for firing. Then a small tube was placed into one of the drilled holes and a short, fat bolt in another hole for the trigger system. The spear was prepared by being sharpened and resized and then filed and drilled on the other end to prepare for shooting.

The last thing to do was make the trigger system. This was the most complicated part, but still not very complicated. We used a piece of metal for the trigger tied on by tire rubber and a nail for the spear release.

Once this was completed there was only one thing left to do: test it.

Testing the Finished Product

With the speargun loaded we tested it by shooting it into the sand several times. We couldn’t have been more pleased with its performance. Now, I need to give it the real test and take it out into the water!

People typically use what they have or can find to make their spearguns. The only things purchased in town are the metal for the spears and the rubber needed. Everything else people collect over time or ask around for. Because of this it can take a while for a gun to be made. Another thing is that the parts of the speargun often need replacing. This is because the saltwater corrodes the metal parts of the gun and the wood for the speargun isn’t usually varnished like mine is. Personally, I plan to care for the metal parts of my gun to slow down the breakdown process. Also, the rubber will need to be replaced over time. Because of these two things, most everyone I know has a speargun that is currently out of commission. At the same time, like mentioned earlier, most young men have a functioning gun ready to use.

Like I shared above, my goal in building this speargun was not only part culture study, but also part relationship building with my friend and part preparation for hopefully many future shared experiences as I continue to build relationships with the young guys on our island.

Our hope is to see the Tigak church build into maturity and to do so means seeing a generation of men and women brought into relationship with Jesus Christ and built up in Him! Please continue to pray for the Tigak church.

[A more detailed explanation of the process along with a parts list and recommended tools list to make your own speargun is available. Contact me if you’re interested.]

pam says

Great blog! Love how innovative everyone is. May God bless your work. Nothing we do for the Lord is wasted. 🙂